ITEC TUBE BENDING

ITEC offers a complete range of innovative tube cutting, bending, punching and forming machinery. Their focus is making high quality, high technology equipment attainable to all size tube fabrication companies.

ITEC offers a complete range of innovative tube cutting, bending, punching and forming machinery. Their focus is making high quality, high technology equipment attainable to all size tube fabrication companies.

ITEC’s goal isn’t to sell tube-bending machines. They want to connect you with the right tube bending solution – one that will match the needs you have today and the goals you have for tomorrow. By design, they are neither a manufacturer nor a distributor. Their priority is on our partners. They create solutions and distribute potential so you can get the job done right the first time. Their Unique Product? Experience. Bringing over 250 years of tube-bending experience to your project.

Manufacturer of arguably the largest range of tube, pipe and profile bending and rolling machines in the world.

From simple 2-axis NC hydro-electric tube and pipe bending machines to fully electric multistack boosted bending machines and some of the largest rotary draw and section benders in the world, AMOB has got you covered!

Employing over 140 team members and relying on over 60 years experience, all of the machines are built in AMOB’s recently revitalized, state of the art almost 200,000 sq ft fully integrated manufacturing facility located near Porto, Portugal.

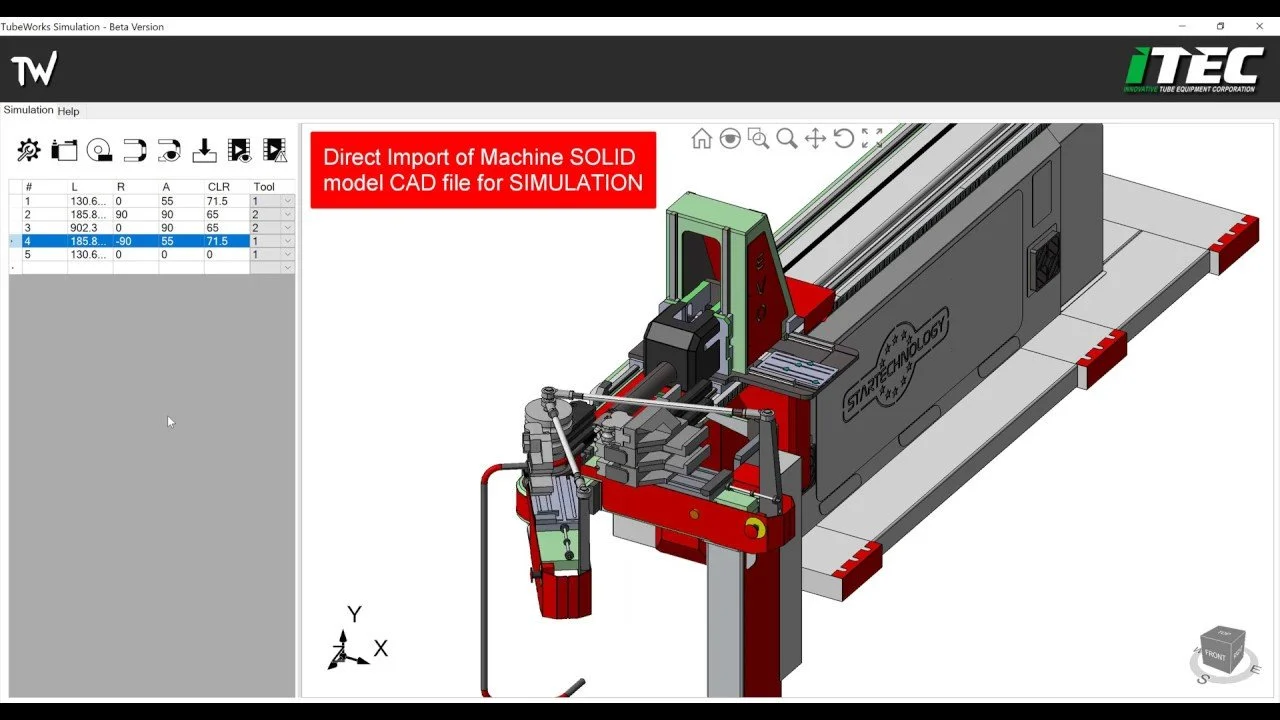

Star Technology designs and manufactures CNC tube benders for processing, punching, deformation and finishing of the tube, special equipment and automation or control requests. They have always produced electromechanical pipe benders: our modernity, precision, speed, silence, safety, reliability and environmental respect have been proven to be successful with respect to traditional hydraulic benders.

TubeWorks software extracts the necessary information such as bend angles and rotations from an imported part (e.g., IGS, Step, or Parasolid), for quotation or production purposes.

TubeWorks is compatible with native SOLIDWORKS models as well as common IGES, and Parasolid.

Once the LRA data is obtained from the geometry, the software can send the data directly to your CNC bender.

Furthermore, it creates a flat configuration of the bend tube with additional automatic functionalities to deduct length due to elongation after the bend. Key features include extract tube specification, automated centerline creation, fully searchable tooling log, tooling recommendation, automated XYZ creation, automated LRA (YBC) creation, centerline total length, calculator automated 2D drawing, generation automated conversion of imported tube models into native SolidWorks models for CLR modification, flatten tube configuration, automated length deduction, and spring back calculations.

Fill out the form below and a representative will be in touch shortly.