HK FIBER Laser

Tube Processing

The HK Fiber laser tube processing line up excels in efficiency, precision, performance, reliability, and consistent results for manufacturing and fabrication industries.

The HK Fiber laser tube processing line up excels in efficiency, precision, performance, reliability, and consistent results for manufacturing and fabrication industries.

Introducing the HK Tube Laser Cutting System—the ultimate solution for precision tube processing. Designed to handle everything from regular tube cutting to structural steel applications like I-beams, angles, and C-channels, our system utilizes advanced optical technology with high-power cutting heads for both straight-down and bevel cutting.

The user-friendly bus-based CNC control system features a 21.5-inch touch screen, enhancing ease of use and accuracy. With multiple sophisticated chuck systems available, the HK Tube Laser Cutting System is tailored to meet diverse industrial needs.

Explore the range below - Each of these machines is tailored to provide optimal performance and versatility for a wide range of industrial tube processing needs.

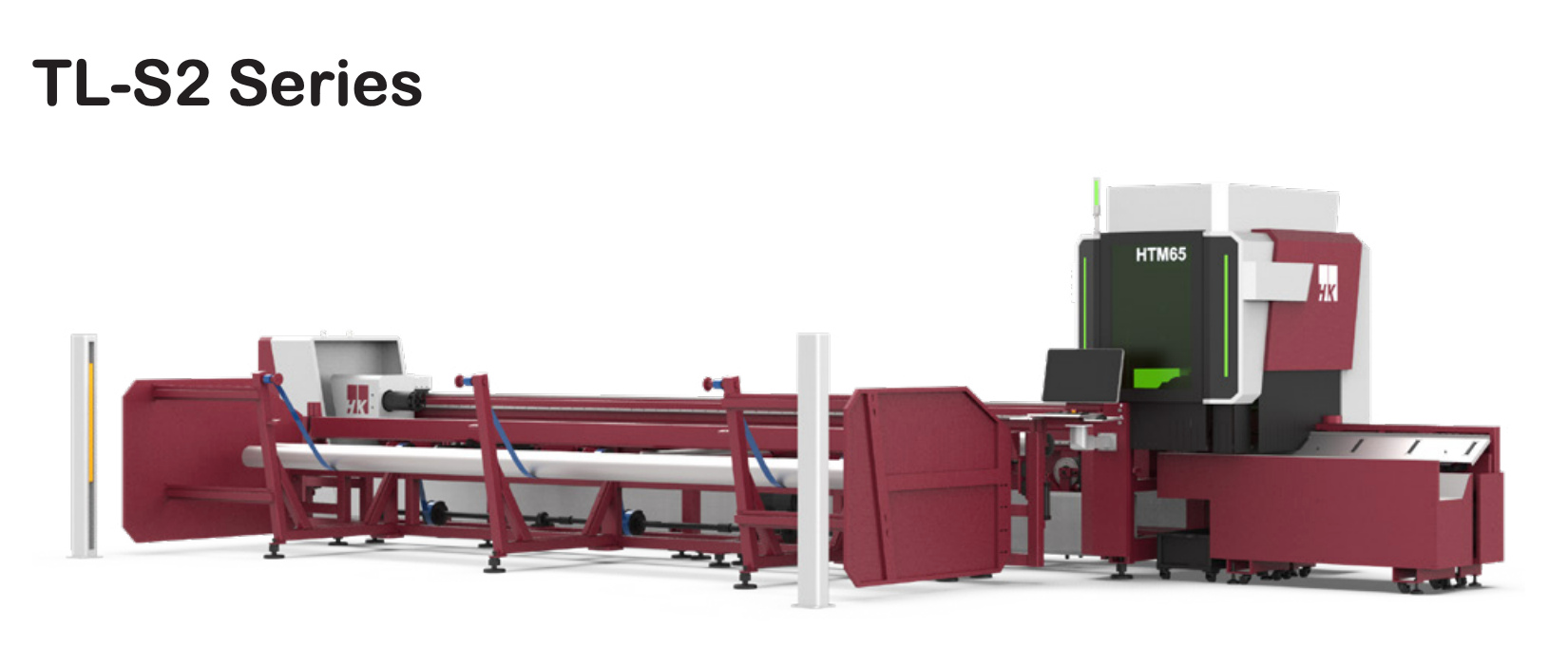

The TL-S2 Series stands out as our most popular solution for efficient and precise tube cutting. This series is designed to enhance productivity with its advanced automated bundle loading system, which allows for continuous operation without manual intervention.

The system's rectangular-circle pneumatic chucks ensure a secure grip on tubes of various shapes, providing stability during the cutting process.

The TL-S2 Series is ideal for industries that demand high-speed production and consistent quality.

Equiped with rectangular-circle pneumatic chucks

Power from 1500 to 6000W for all cutting needs

21.5 inch touch screen with interface

Automated Bundle Loading: Reduces downtime by enabling seamless transitions between cuts, allowing for increased throughput.

Rectangular-Circle Pneumatic Chucks: Provide reliable clamping for a variety of tube geometries, ensuring precise cuts every time.

21.5-inch Touch Screen Interface: Offers a user-friendly experience with easy access to cutting parameters and system controls.

Digital Chuck System: Facilitates automatic clamping setup, minimizing manual adjustments and setup time.

Specifications:

Power: 1.5-6 kW, accommodating a wide range of cutting applications.

Tube Diameter: Handles up to 10 inches.

Tube Length: Up to 26 feet.

Single Tube Weight: Supports up to 440 lbs.

Tailing Length: As short as 3.3 inches.

The TL-S Series is an economical solution tailored for businesses seeking efficient tube cutting without compromising on quality.

This series is designed to offer reliable performance at a cost-effective price point, making it accessible to a wide range of industries.

With its high-speed rotating chucks, the TL-S Series ensures quick and accurate cuts, making it ideal for production environments with high volume demands.

High performance tube cutting solution with a complete automated bundle loading system

Maximum diameter up to 10 inches and tube length up to 26 ft

Digital chuck system that enables automatic clamping setup

Economic Solution: Provides essential cutting capabilities while maintaining a focus on cost efficiency.

High-Speed Rotating Chucks: Enable rapid and precise cutting, reducing cycle times.

Intuitive Interface: Simplifies operation with an easy-to-use control panel.

Versatile Design: Accommodates various tube shapes and sizes, from round to rectangular profiles.

Specifications:

Power: 3-6 kW, suitable for medium to heavy-duty cutting tasks.

Tube Diameter: Supports up to 9.4 inches.

Tube Length: Capable of processing tubes up to 26 feet.

Rotating Speed of Chucks: 120 RPM.

Single Tube Weight: Manages up to 440 lbs per tube.

The TL-X Plus Series is engineered for high-performance tube cutting, offering enhanced automation and precision for demanding applications.

This series is equipped with a full-scale automated bundle loading system, enabling uninterrupted production.

The digital chuck system allows for quick and precise clamping adjustments, making it ideal for complex cutting tasks that require high accuracy and efficiency.

Heavy duty with side mounted chuck system and automated front loading system

Max diameter up to 12.7 inches (optional 13.7 inches) tube length up to 40ft

Full-Scale Automated Bundle Loading: Streamlines the cutting process, maximizing productivity and minimizing human intervention.

Digital Chuck System: Ensures precise and automatic clamping setup, reducing the risk of errors.

21.5-inch Touch Screen: Provides intuitive control over cutting operations, allowing for easy monitoring and adjustments.

Versatile Cutting Capabilities: Designed to handle complex shapes and varied materials with ease.

Specifications:

Power: 3-12 kW, offering flexibility for a wide range of cutting demands.

Tube Diameter: Handles up to 12.7 inches.

Tube Length: Ranges from 21 to 39 feet.

Single Tube Weight: Capable of supporting 1,322 lbs per tube.

The TL-P Series is specifically designed for heavy-duty applications, featuring a robust side-mounted chuck system and an automated front-loading mechanism.

This series excels in processing complex geometries and large structural components, thanks to its 45-degree bevel cutting head.

The TL-P Series is perfect for industries that require reliable performance for intricate and challenging tube-cutting tasks.

Includes same features as TL-S series

Extra features include: 45 degree bevel cutting head

Heavy-Duty Side-Mounted Chuck System: Provides enhanced stability and support for heavy and large-diameter tubes.

Automated Front-Loading System: Facilitates easy handling and positioning of tubes, improving workflow efficiency.

45-Degree Bevel Cutting Head: Enables precise angled cuts for complex designs and structural applications.

Designed for Structural Components: Ideal for cutting beams and other large-scale elements.

Specifications:

Power: 3-6 kW, suitable for demanding cutting tasks.

Tube Diameter: Up to 12.7 inches, with an optional extension to 13.7 inches.

Tube Length: Supports tubes up to 40 feet.

Rotating Speed of Chucks: 120 RPM.

Single Tube Weight: Handles up to 440 lbs per tube.

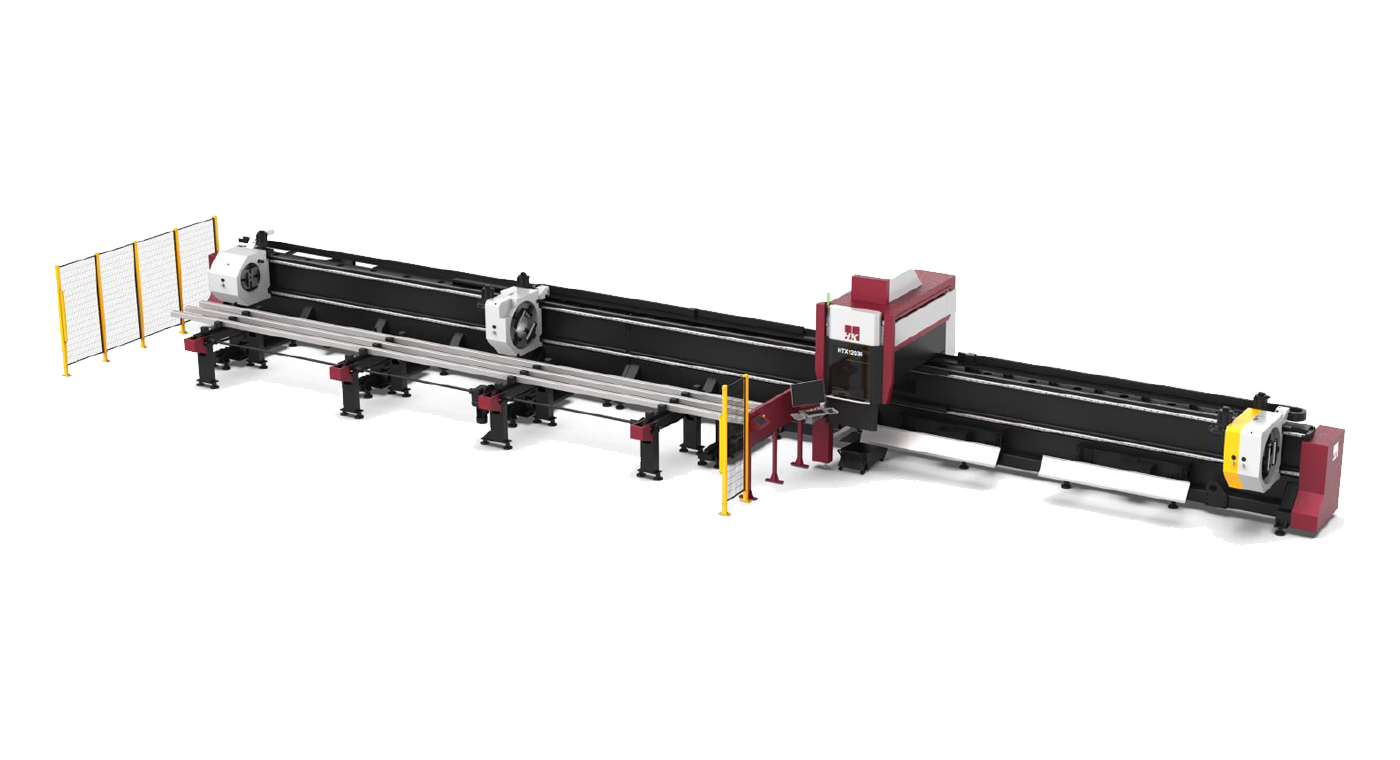

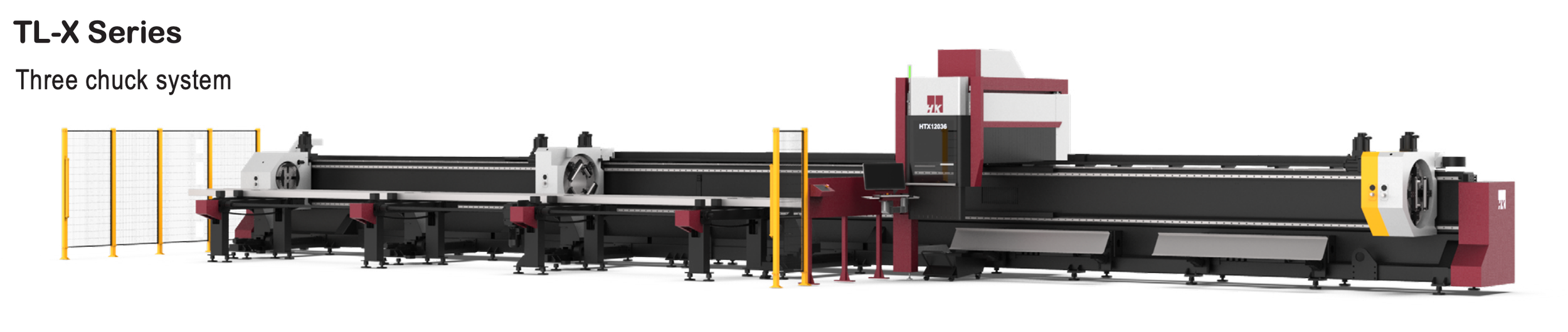

The TL-X Series is designed for heavy-duty tube cutting, offering exceptional stability and precision with its 3+1 Twin chuck system.

This series is ideal for processing large structural beams, including I/H/Angle beams, and features a full-scale automated loading/unloading system to maximize efficiency and productivity.

Heavy duty tube cutting with side mounted 3+1 Twin chucks

Diameters up to 14.1 inches for structural I/H/Angle beams

Maximum tube length up to 40 ft (optional 50 ft)

Heavy-Duty Cutting for Structural Beams: Provides robust performance for processing large and complex beam profiles.

3+1 Twin Chuck System: Enhances stability and precision during cutting, ensuring consistent results.

Automated Loading/Unloading System: Optimizes workflow by minimizing manual handling and setup time.

Supports Large Tube Diameters and Lengths: Accommodates oversized tubes for a variety of industrial applications.

Specifications:

Power: 6-12 kW, capable of handling high-demand cutting operations.

Tube Diameter: Up to 14.1 inches.

Tube Length: Supports tubes up to 40 feet, with an optional extension to 50 feet.

Single Tube Weight: Can support up to 1,322 lbs per tube.

The TL-L Series is engineered for the most demanding applications, featuring a four-chuck system that provides maximum clamping force and stability.

This series is ideal for processing oversized and heavy tubes, ensuring precision and efficiency in even the toughest cutting tasks.

Heavy duty tube cutting with four chucks with a full-scale automated loading/unloading system

Diameters up to 20 inches

Maximum tube length up to 40 ft (optional 50 ft)

Four Chuck System: Delivers superior clamping stability for heavy-duty applications, reducing vibrations and improving cut quality.

Maximum Stability for Large and Long Tubes: Designed to handle tubes up to 20 inches in diameter and up to 50 feet in length.

Advanced Automation: Includes a full-scale automated system for loading and unloading, enhancing operational efficiency.

Suitable for Oversized and High-Weight Materials: Capable of processing tubes with significant weight and size, meeting the needs of heavy industry.

Specifications:

Power: 6-12 kW, offering powerful performance for extensive cutting needs.

Tube Diameter: Handles up to 20 inches.

Tube Length: Supports up to 40 feet, with options for extension to 50 feet.

Single Tube Weight: Can manage up to 2,645 lbs per tube.

Fill out the form below and a representative will be in touch shortly.