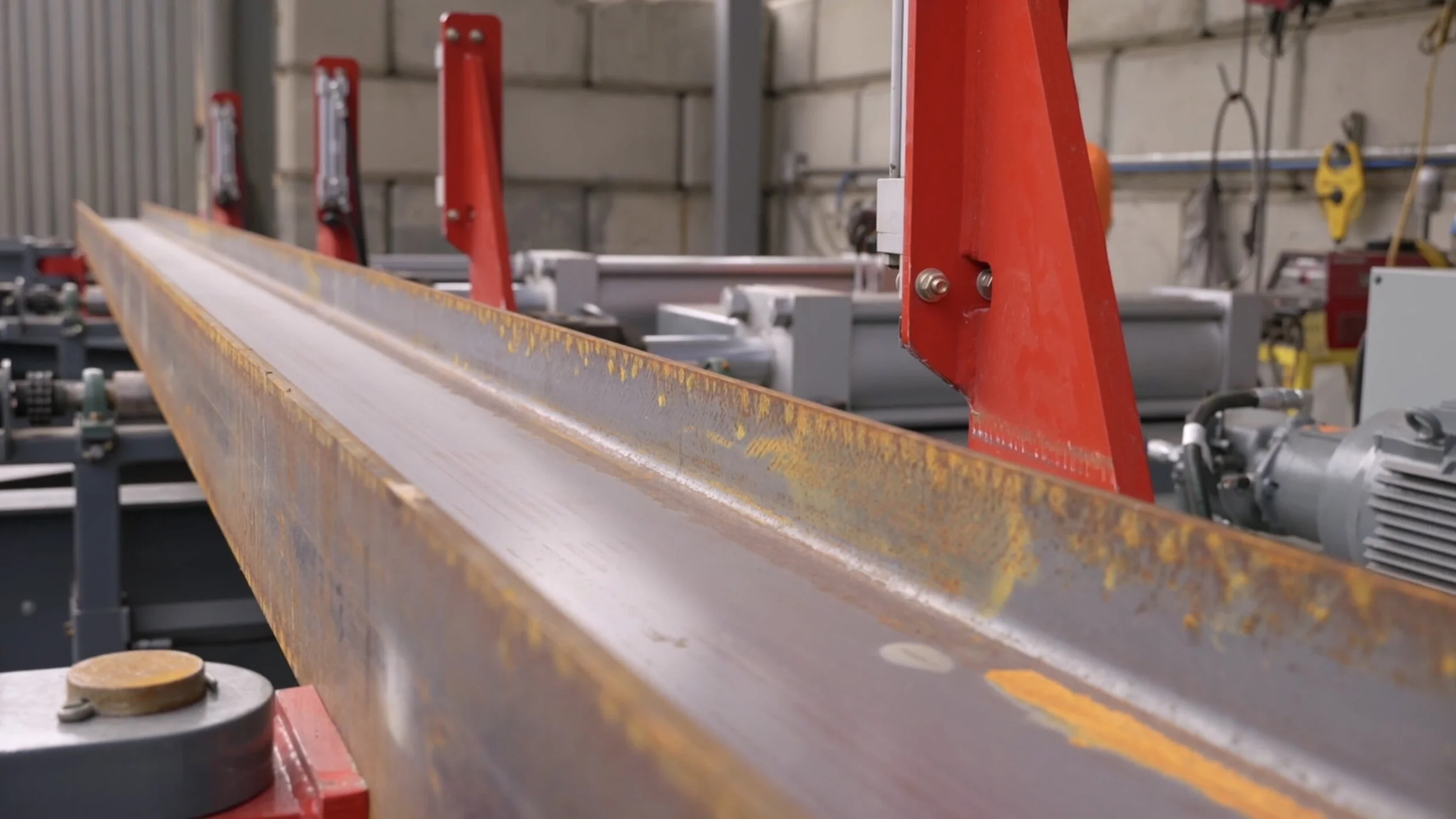

Bay-Lynx Cambering Machines

Bay-Lynx developed their first commercially available beam cambering machine for the structural fabrication industry over two decades ago for their own Steel Fabrication shop. Their machines allow fabricators to camber beams at a fraction of the cost of a service center or heat cambering.